Article by Jesse Morton from Engineering and Mining Journal, October Edition 2023

Making the Complex Simple

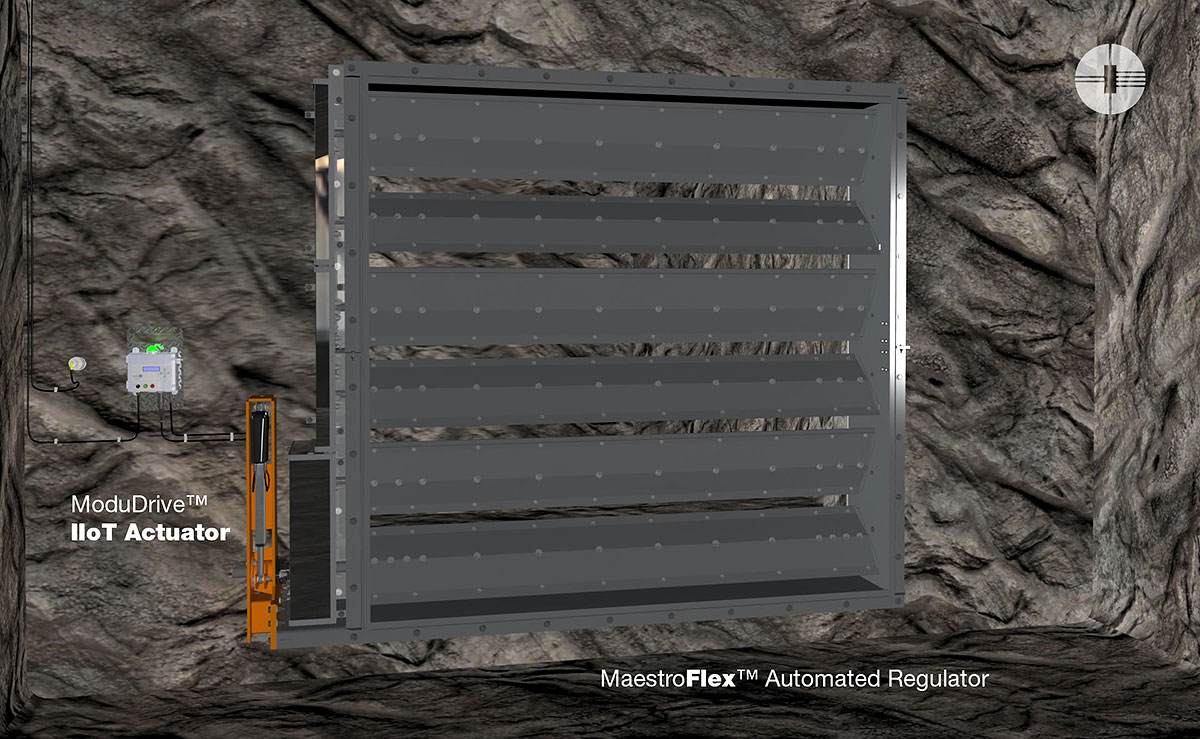

Maestro Digital Mine announced the integration of MaestroFlexTM Automated Regulators and ModuDriveTM IIoT Linear Actuators to allow the customer to set air quality sensor value thresholds from the surface. The solution empowers the actuators to dynamically adjust regulators to maintain precise environmental levels, leadership at the supplier said.

“The breakthrough lies in our dynamic edge-based decision capability integrated into the ModuDrive system,” said Jahanzeb Sohail, P.Eng., chief operating officer. The system’s ability to maintain local control independent of the service network, even during downtime, “adds a layer of resilience that the industry has never seen before.”

The solution offers improved safety underground by helping ensure workers are protected from harmful gas exposure. “It doesn’t stop there,” he said. “It also allows the capability to reduce blast clearance times, enhancing productivity and allowing miners to return to work quicker and safer.”

The “pivotal” innovation can be used to “not only safeguards lives but boost efficiency and sustainability in underground mining,” Sohail said. “In 2023, we are paving the way for a safer, more productive and environmentally responsible mining future.”

The development furthers the company’s range of cutting-edge air quality, VOD, and communication solutions for underground mining. For ventilation applications, the supplier offers sensors and systems for continuous air quality monitoring. The sensor and system data “is processed, analyzed, and provides actual insights into operating environments,” Sohail said. “A lot of the mines operate it to proactively address any potential air quality issues, ensuring safety and productivity excellence.”

A Maestro air quality monitoring system is reportedly easy to install, use, maintain, and grow, compared to an in-house system built piecemeal by a miner. It offers lower CapEx and OpEx, Sohail said.

“Our solution reduces CapEx by selling a multivariable device to customers with everything tying into one IP address,” he said. It can offer reduced engineering costs, simplified and streamlined integration, and has low infrastructure requirements.

“For example, your gas sensors, your air flows, differential pressure, and the list goes on,” can all be tied to one IP address, Sohail said.

Maestro air quality system solutions can shorten an installation project schedule by “allowing devices to be scaled and modularized,” which also allows “for the ever-expanding mine operations over time,” he said. “It allows the IoT solutions to basically be scalable, manageable and maintainable, for every factor of the mine, especially operators…”

Read the full article in the International Mining Magazine here.