One of the most important aspects of underground hard rock mining is ventilation.

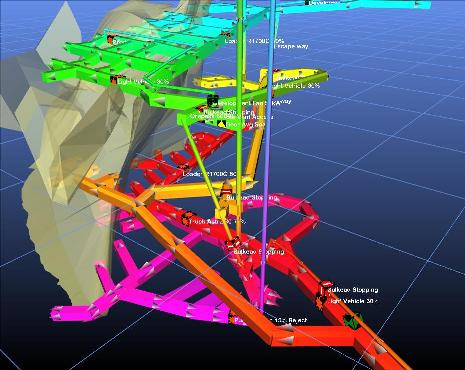

Ventilation is required to clear toxic fumes from blasting and removing exhaust fumes from diesel equipment. In deep hot mines ventilation is also required for cooling the workplace for miners. Ventilation raises are excavated to provide ventilation for the workplaces, and can be modified for use as emergency escape routes. The primary sources of heat in underground hard rock mines are virgin rock temperature, machinery, auto compression, and fissure water. Other small contributing factors are human body heat and blasting.

Maestro's Air Quality Stations are used in all of the top 10 global hard rock mining companies. Our clients' tell us that the ease of installation, user flexibility and reduction of both hardware are the top considerations for their decision to deploy our systems.

Integration of Maestro's Vigilante AQS monitoring systems can lead to significant productivity improvements with respect to blast clearance times, energy savings with directing fresh air to the working locations, health and safety advances and at the same time reduce the heavy labor burden of "walk around samplings".