Exyn and Maestro Digital Mine’s partnership highlights a continued effort to enhance worker safety in the mining industry

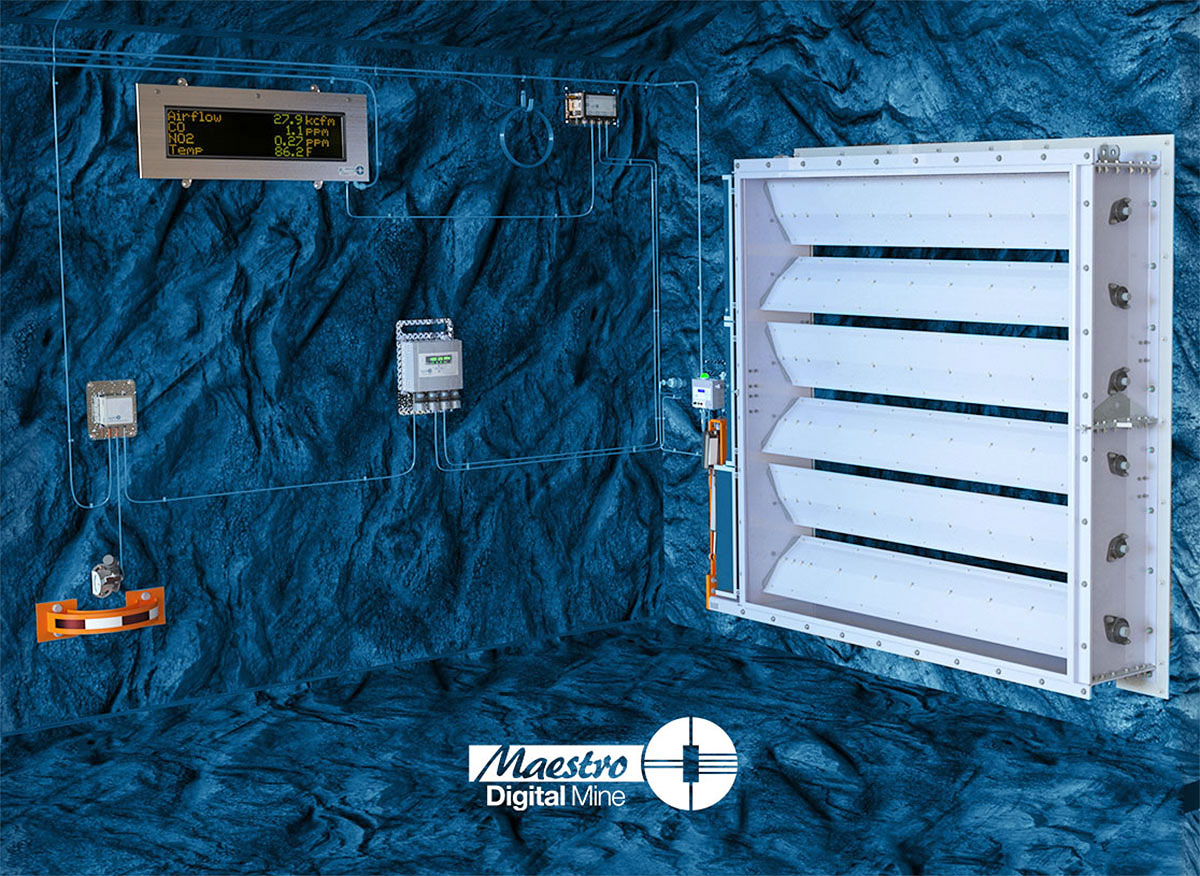

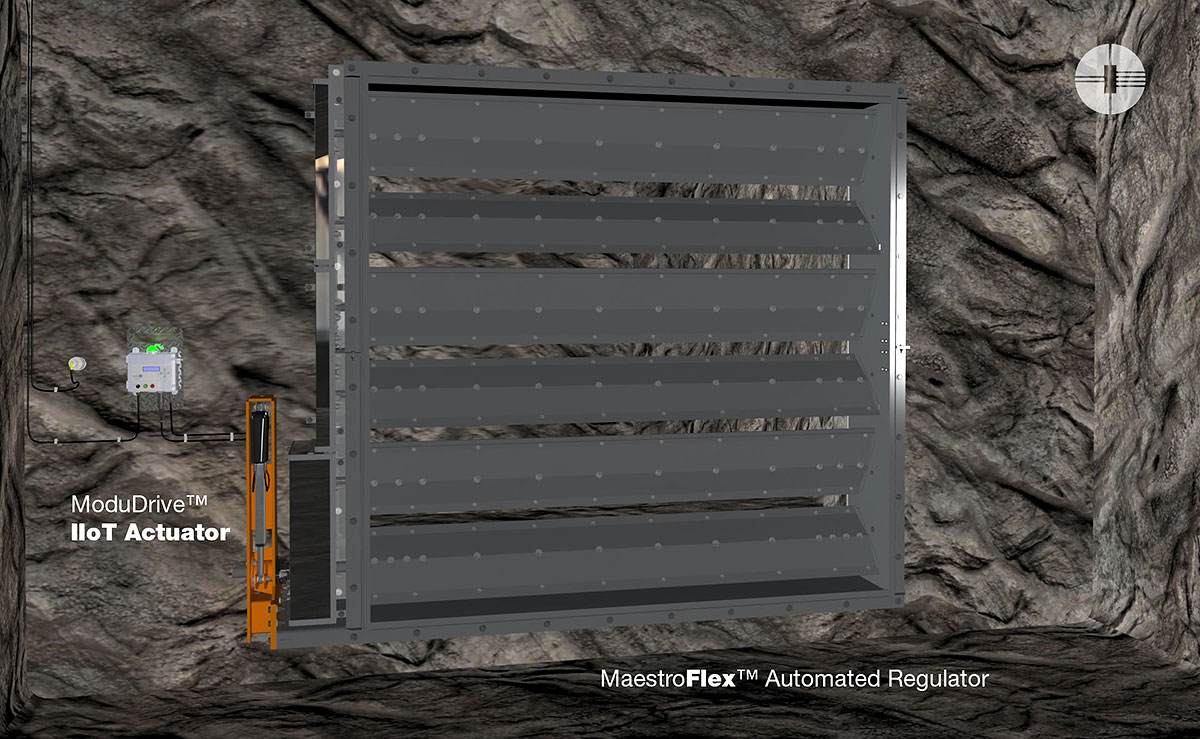

February 28th – Philadelphia, PA – Exyn Technologies, a pioneer in multi-platform autonomy for complex, GPS-denied industrial environments, today announces a partnership with Maestro Digital Mine, a manufacturer specializing in Industrial Internet of Things (IIoT) devices to give mining teams up-to-the-minute information about worker safety underground by integrating critical gas sensors onto the ExynAero™ and ExynPak™. This partnership highlights both companies' continued efforts to improve worker safety and productivity in the mining industry.

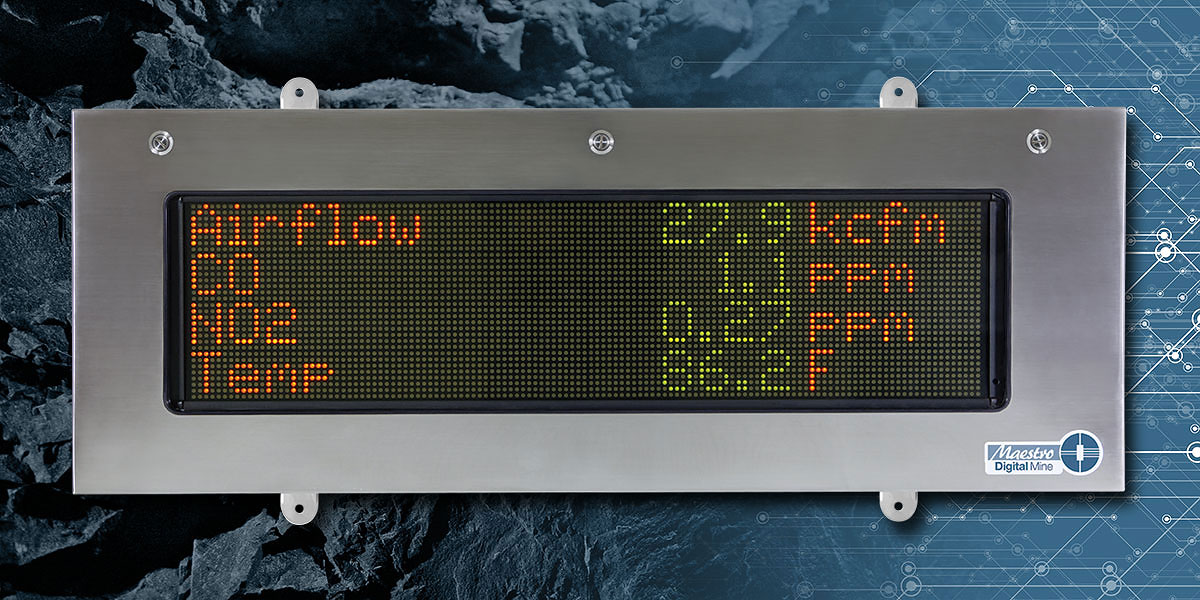

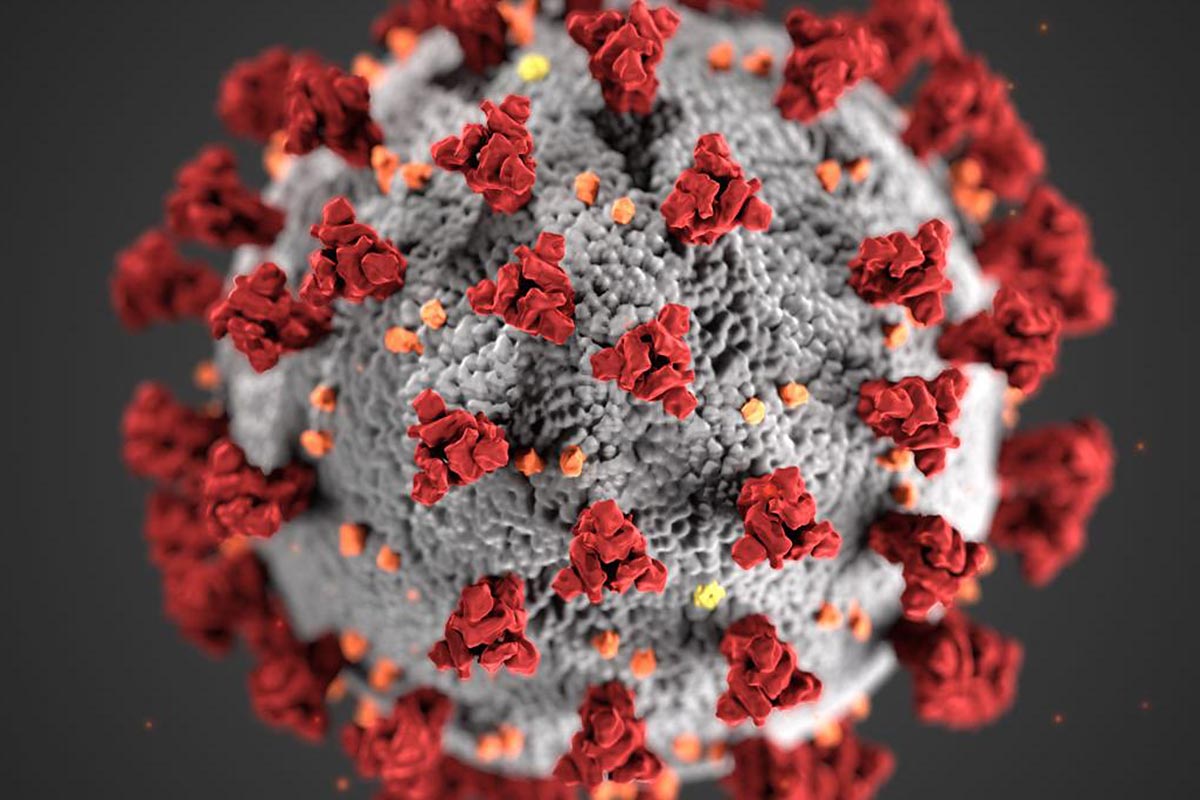

Hazardous gasses underground are an invisible threat to mining teams, who often don't know they are in danger until it's too late. This gas buildup can be created through the exposed strata, blasting, daily "mucking" and even runaway battery fires on critical machinery. Traditionally, the gas levels are measured by the ventilation system at the return air raises or wearable sensors donned by miners. And while these innovations have saved countless lives, they don’t allow a manless inspection of the headings before re-entry or in emergency situations.

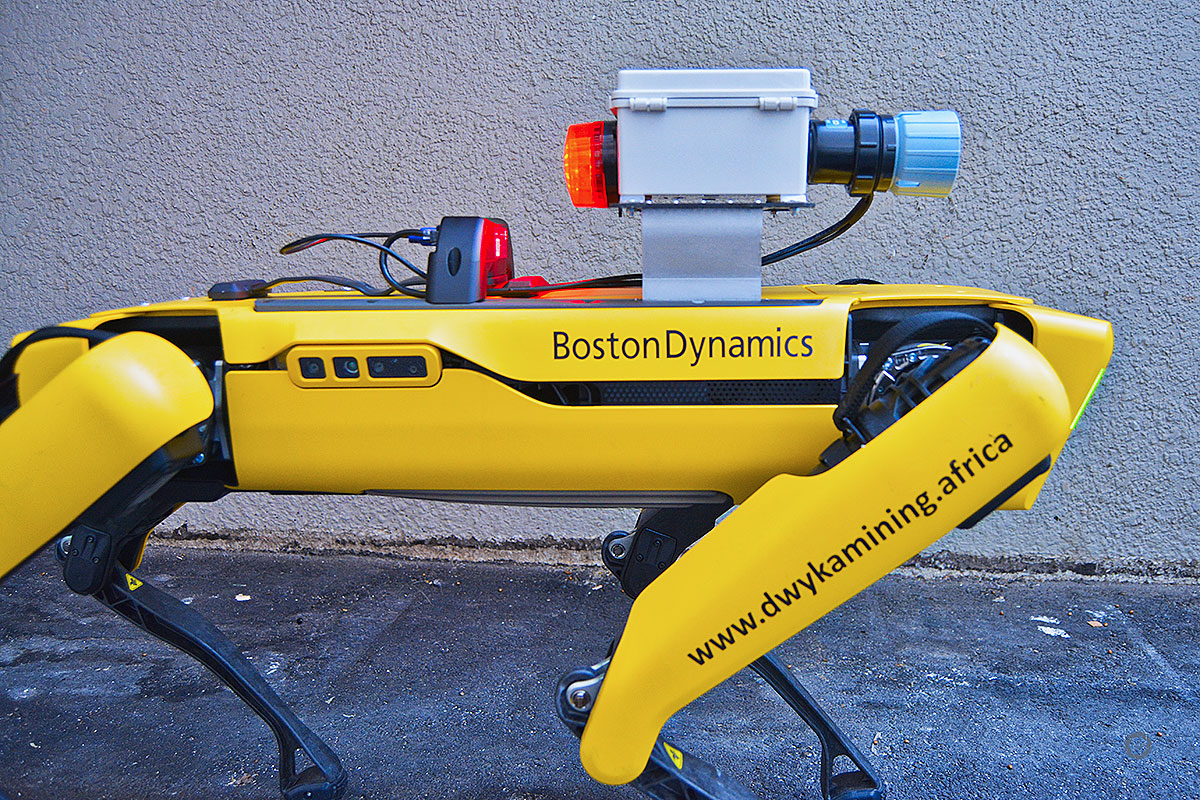

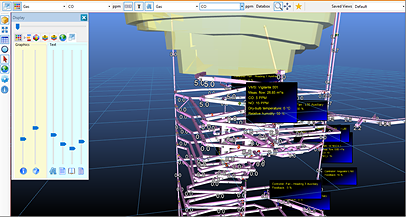

Now the ExynAero, a fully autonomous drone for exploring and mapping GPS-denied environments, equipped with Maestro’s IIoT gas sensor can be flown down drifts or into stopes to detect and localize any hazardous gasses without putting mining and survey teams in danger. Survey teams can easily add different gas sensors onto an ExynPak and mount it to the front of a truck or loader to capture the same gas sensor data while mapping drifts or moving ore, capturing critical data while not slowing down daily production.

“In the future, buying an autonomous robot will be similar to online car shopping. Pick your airframe, your preferred level of autonomy, and add in any sensors that fit your specific need,” says Nader Elm, Co-Founder and CEO of Exyn Technologies. "The capabilities of ExynAITM multi-sensor fusion move autonomous robots out of boutique one-to-one use cases and into much broader applications. We're very excited about our first integration with Maestro Digital Mine and look forward to continually improving worker safety below and above ground."

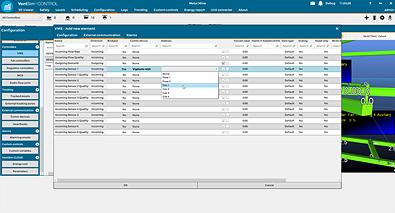

Powered by ExynAI's multi-sensor fusion capabilities, gas sensor readings are captured while the robot is in flight and displayed in real-time via a ruggedized tablet. These sensor readings are saved with precise coordinates in a high-fidelity point cloud that can be exported and examined in a variety of mining software.

With lives and money at risk, the sensor-equipped ExynAero is the next step in improving worker safety in the mining industry.

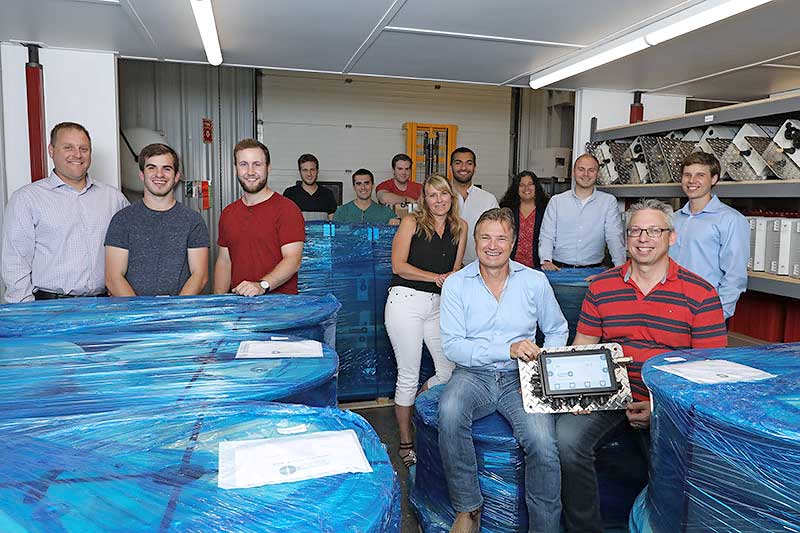

“Collaborating with a world leading autonomous drone manufacturer is another important step to living up to our core purpose of enhancing lives by the pursuit of productivity and safety excellence,” says Michael Gribbons, CEO and Co-Founder of Maestro Digital Mine. "This relationship will open up opportunities to both Exyn and Maestro to expand upon our current installations at over 170 mines in 38 countries globally using our patented edge based IIoT sensor technologies.”

Exyn has successfully commercialized industrial-grade multi-platform autonomy with major customers in mining, construction, and logistics.

About Exyn Technologies

Exyn Technologies is pioneering multi-platform autonomy for complex, GPS-denied environments. The company’s full-stack solution enables flexible deployment of single or multi-robots that can intelligently navigate and dynamically adapt to complex environments in real-time. For the first time, industries like mining, industrial inspection, and construction can benefit from a single, integrated solution to capture critical and time-sensitive data in a safer, more affordable, and more efficient way. Exyn is powered by a team of experts in autonomous systems, robotics, and industrial engineering, and has drawn talent from the University of Pennsylvania's world-renowned GRASP Laboratory. The company is VC-backed and privately held, with headquarters in Philadelphia. For more information, please visit www.exyn.com.

About Maestro Digital Mine

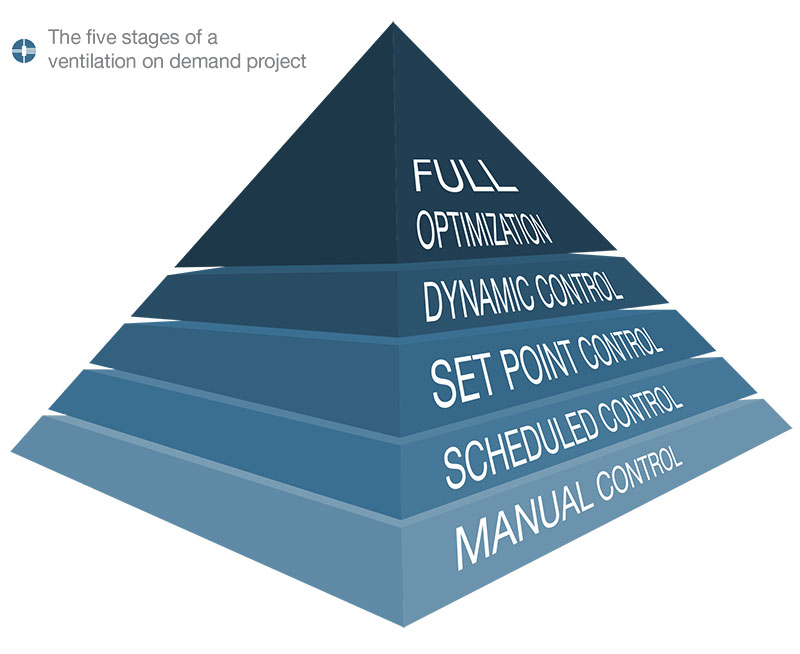

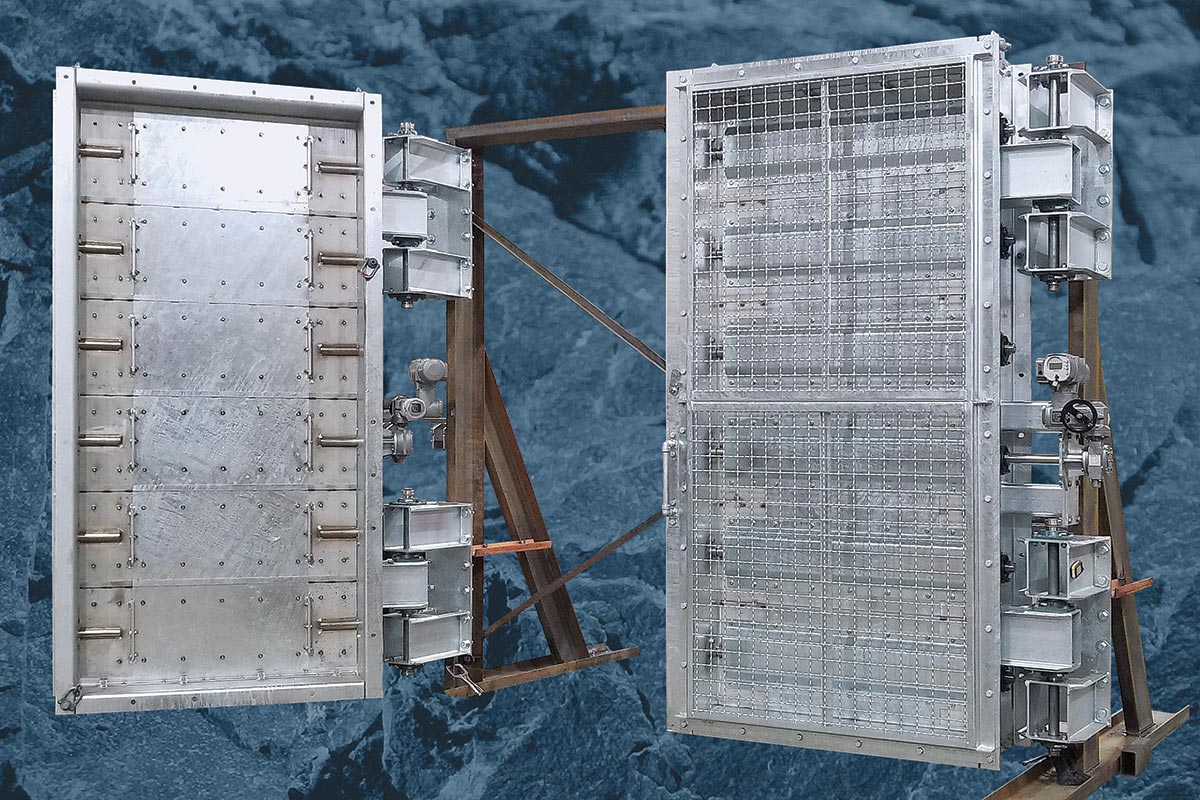

Maestro Digital Mine manufactures Industrial Internet of Things (IIoT) measurement and control instrumentation for the optimization of underground mine ventilation and underground digital networks for last mile communication. Maestro products are made exclusively for the underground mine automation, IT, and ventilation sectors, delivering energy savings and productivity improvements while meeting the highest health and safety standards. Learn more about Maestro’s digital solutions at www.maestrodigitalmine.com.

Maestro Contact:

Nataly Argüello

Marketing Manager

This email address is being protected from spambots. You need JavaScript enabled to view it.

Office: 1-705-805-6918, x 218

See Press Release on Exyn’s website here.

Media Coverage:

Drones are new canaries in the mine

Metal Tech News

Maestro Digital Mine, which specializes in industrial internet of things (IIoT) devices that make mines safer and more productive, and Exyn Technologies, a pioneer of aerial drones capable of autonomously navigating complex underground environments, have teamed up to create the 21st century equivalent of a canary in the mine – an ExynAero drone equipped with critical gas sensors manufactured by Maestro. Read more here.

Exyn Technologies Partners with Maestro Digital Mine to Expand ExynAI’s Multi-Sensing Capabilities

Mine Connect

Exyn Technologies, a pioneer in multi-platform autonomy for complex, GPS-denied industrial environments, today announces a partnership with Maestro Digital Mine, a manufacturer specializing in Industrial Internet of Things (IIoT) devices to give mining teams up-to-the-minute information about worker safety underground by integrating critical gas sensors onto the ExynAero™ and ExynPak™. This partnership highlights both companies’ continued efforts to improve worker safety and productivity in the mining industry. Read more here.

Exyn Technologies partners with Maestro to improve worker safety in mining

Canadian Mining Journal

Exyn Technologies, a pioneer in multi-platform autonomy for complex, GPS-denied industrial environments, today announces a partnership with Maestro Digital Mine, a manufacturer specializing in Industrial Internet of Things (IIoT) devices to give mining teams up-to-the-minute information about worker safety underground by integrating critical gas sensors onto the ExynAero and ExynPak. This partnership highlights both companies' continued efforts to improve worker safety and productivity in the mining industry. Read more here.

Exyn Technologies partners with Maestro to improve worker safety in mining

Mining.com

Exyn Technologies, a pioneer in multi-platform autonomy for complex, GPS-denied industrial environments, announced Monday a partnership with Maestro Digital Mine, a manufacturer specializing in Industrial Internet of Things (IIoT) devices to give mining teams up-to-the-minute information about worker safety underground by integrating critical gas sensors onto the ExynAero and ExynPak. This partnership highlights both companies’ continued efforts to improve worker safety and productivity in the mining industry. Read more here.

Exyn Technologies partners with Maestro Digital Mine

Global Mining Review

Exyn Technologies, a pioneer in multi-platform autonomy for complex, GPS-denied industrial environments, has announced a partnership with Maestro Digital Mine, a manufacturer specialising in Industrial Internet of Things (IIoT) devices, to give mining teams up-to-the-minute information about worker safety underground by integrating critical gas sensors onto the ExynAeroTM and ExynPakTM. This partnership highlights both companies' continued efforts to improve worker safety and productivity in the mining industry. Read more here.

Exyn Technologies Partners with Maestro Digital Mine to Expand ExynAI’s Multi-Sensing Capabilities

MSTA Canada (Mining Suppliers Trade Association Canada)

February 28th — Philadelphia, PA — Exyn Technologies (https://www.exyn.com), a pioneer in multi-platform autonomy for complex, GPS-denied industrial environments, today announces a partnership with Maestro Digital Mine, a manufacturer specializing in Industrial Internet of Things (IIoT) devices to give mining teams up-to-the-minute information about worker safety underground by integrating critical gas sensors onto the ExynAero™ and ExynPak™. This partnership highlights both companies’ continued efforts to improve worker safety and productivity in the mining industry. Read more here.

Exyn Technologies partners with Maestro Digital Mine to expand ExynAI's multi-sensing capabilities

Sudbury Mining Solution Journal

PHILADELPHIA, PA — Feb. 28: Exyn Technologies, a pioneer in multi-platform autonomy for complex, GPS-denied industrial environments, today announces a partnership with Maestro Digital Mine, a manufacturer specializing in Industrial Internet of Things (IIoT) devices to give mining teams up-to-the-minute information about worker safety underground by integrating critical gas sensors onto the ExynAero™ and ExynPak™. This partnership highlights both companies' continued efforts to improve worker safety and productivity in the mining industry. Read more here.

Exyn Technologies partners with Maestro to improve worker safety in mining

Markets Insider

Exyn Technologies, a pioneer in multi-platform autonomy for complex, GPS-denied industrial environments, announced Monday a partnership with Maestro Digital Mine, a manufacturer specializing in Industrial Internet of Things (IIoT) devices to give mining teams up-to-the-minute information about worker safety underground by integrating critical gas sensors onto the ExynAero and ExynPak. This partnership highlights both companies’ continued efforts to improve worker safety and productivity in the mining industry. Read more here.

Exyn Technologies partners with Maestro to improve worker safety in mining

Market Trading Essentials

Now the ExynAero, a fully autonomous drone for exploring and mapping GPS-denied environments, equipped with Maestro’s IIoT gas sensor can be flown down drifts or into stopes to detect and localize any hazardous gasses without putting mining and survey teams in danger. Survey teams can easily add different gas sensors onto an ExynPak and mount it to the front of a truck or loader to capture the same gas sensor data while mapping drifts or moving ore, capturing critical data while not slowing down daily production. Read more here.

Exyn Technologies partners with Maestro to improve worker safety in mining

i-Mine

Exyn Technologies, a pioneer in multi-platform autonomy for complex, GPS-denied industrial environments, announced Monday a partnership with Maestro Digital Mine, a manufacturer specializing in Industrial Internet of Things (IIoT) devices to give mining teams up-to-the-minute information about worker safety underground by integrating critical gas sensors onto the ExynAero and ExynPak. This partnership highlights both companies’ continued efforts to improve worker safety and productivity in the mining industry. Read more here.

News from SME 2022: Maestro, Exyn partner for worker safety

Miners News

Exyn Technologies announced this week that it has come together in partnership with Industrial Internet of Things (IIot) device group Maestro Digital Mine to boost safety and production with the use of the fully autonomous ExynAero drone. Specifically, according to the companies, the ExynAero can be utilized for exploring and mapping GPS-denied environments, and since it is equipped with Maestro’s IIoT gas sensor it has the capability for flights down drifts or into stopes to detect and localize hazardous gasses without putting personnel in danger. Read more here.

Exyn Technologies partners with Maestro Digital Mine

Mining Frontier

Exyn Technologies, a pioneer in multi-platform autonomy for complex, GPS-denied industrial environments, has announced a partnership with Maestro Digital Mine, a manufacturer specialising in Industrial Internet of Things (IIoT) devices, to give mining teams up-to-the-minute information about worker safety underground by integrating critical gas sensors onto the ExynAeroTM and ExynPakTM. This partnership highlights both companies’ continued efforts to improve worker safety and productivity in the mining industry. Read more here.

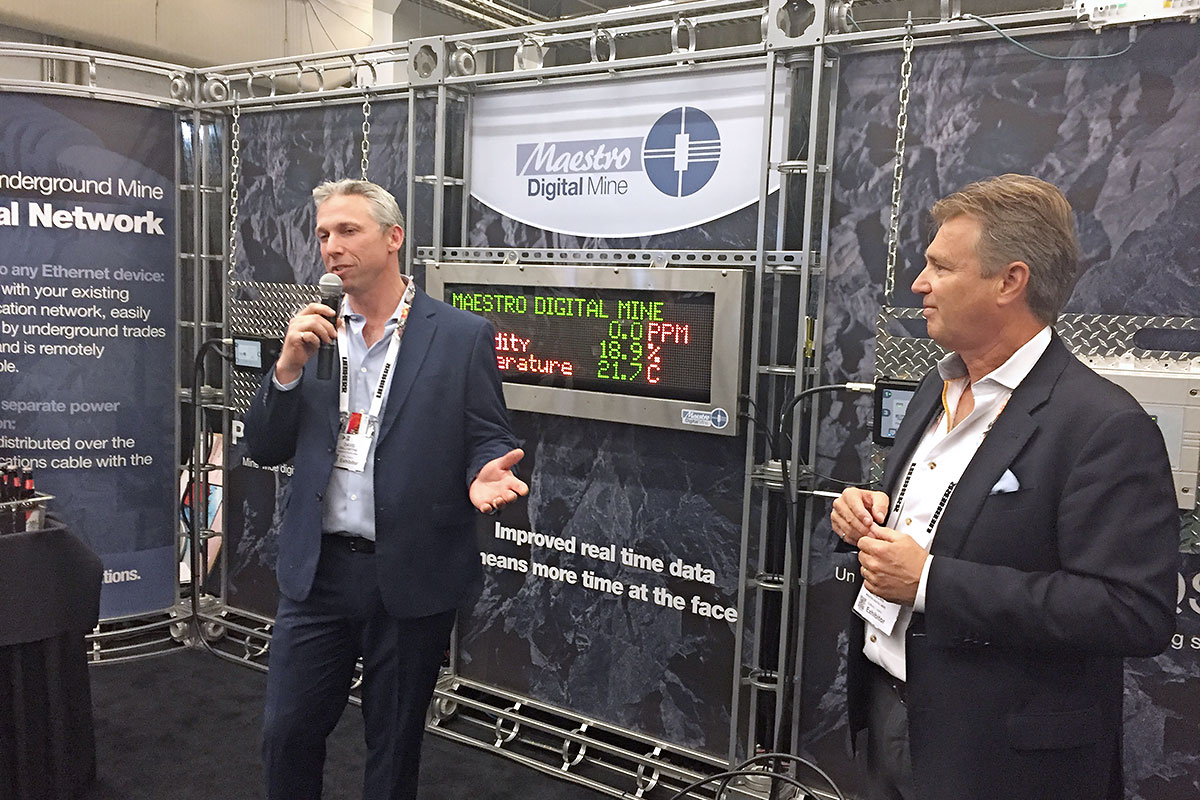

GBR’s interview with Michael Gribbon’s Vice President of Sales and Marketing and Co-founder, Maestro Digital Mine.

GBR’s interview with Michael Gribbon’s Vice President of Sales and Marketing and Co-founder, Maestro Digital Mine.

Despite this, Maestro has gained a reputation for providing ventilation control and environmental monitoring solutions that are ready to cope with the diversities of today’s and tomorrow’s underground mines.

Despite this, Maestro has gained a reputation for providing ventilation control and environmental monitoring solutions that are ready to cope with the diversities of today’s and tomorrow’s underground mines.

The MacLean mobile equipment R&D lab allows the company to develop and test new mining technologies completely in-house. The underground test facility consists of a 300m (1,000 foot) decline (at an average grade of 15%) that branches into multiple headings and testing areas. The facility comes with additional shop and office space providing MacLean engineers and operator trainers the ideal setting for putting mining innovation theory into practice.

The MacLean mobile equipment R&D lab allows the company to develop and test new mining technologies completely in-house. The underground test facility consists of a 300m (1,000 foot) decline (at an average grade of 15%) that branches into multiple headings and testing areas. The facility comes with additional shop and office space providing MacLean engineers and operator trainers the ideal setting for putting mining innovation theory into practice.

The Plexus PowerNet™ coaxial cable carries both power and network connectivity, eliminating the need to run both fiber and power to new network devices. The system can also extend a fiber-optic-based system from the fiber patch panel at any level as needed. Plexus PowerNet™ eliminates the need for costly outside fiber optic contractors and can be installed and maintained by any mine personnel.

The Plexus PowerNet™ coaxial cable carries both power and network connectivity, eliminating the need to run both fiber and power to new network devices. The system can also extend a fiber-optic-based system from the fiber patch panel at any level as needed. Plexus PowerNet™ eliminates the need for costly outside fiber optic contractors and can be installed and maintained by any mine personnel.

The Sudbury-based company was honoured at the 24th annual Bell Business Excellence Awards gala celebration on September 16th at the Caruso Club in Sudbury. Hosted by the Greater Sudbury Chamber of Commerce, the annual awards ceremony pays tribute to entrepreneurs and businesses that demonstrate excellence in their field.

The Sudbury-based company was honoured at the 24th annual Bell Business Excellence Awards gala celebration on September 16th at the Caruso Club in Sudbury. Hosted by the Greater Sudbury Chamber of Commerce, the annual awards ceremony pays tribute to entrepreneurs and businesses that demonstrate excellence in their field.